Water Saving Techniques

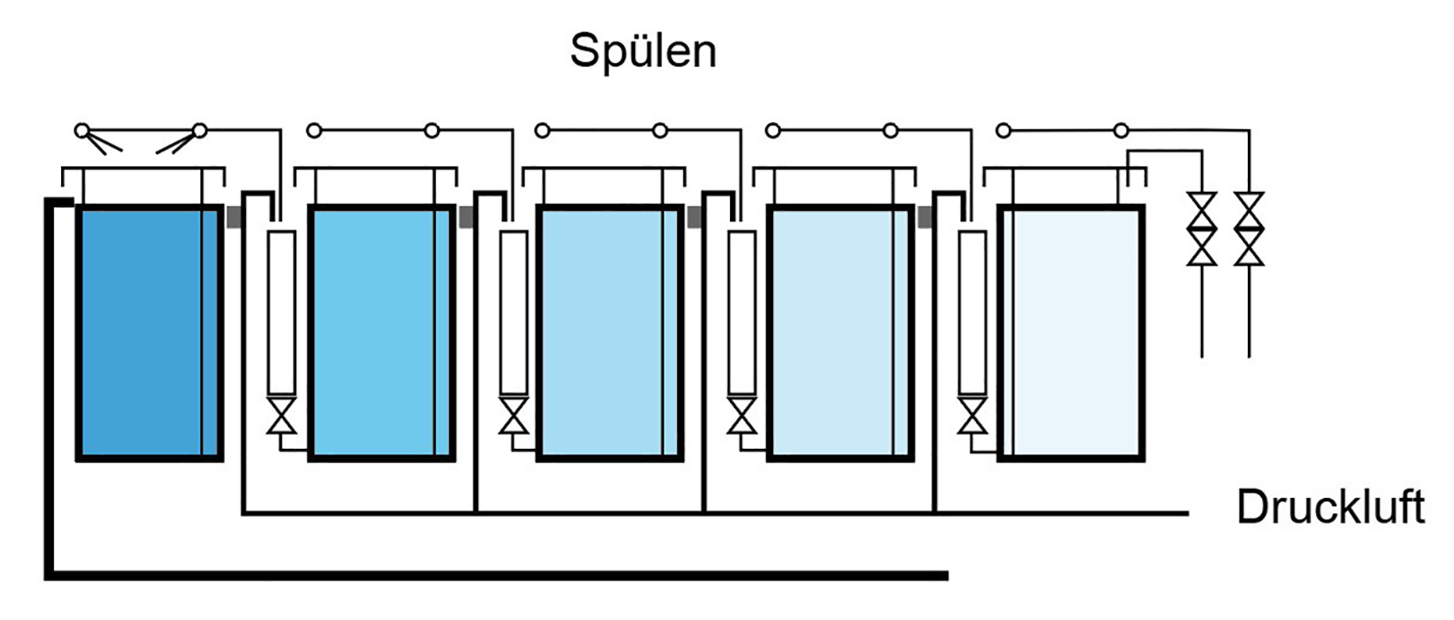

Cascade swills with or without spray swills

The workpieces are washed off in the rinsing baths to reduce the drag-out of active substances. The active substances get into the rinsing water and can be recovered from there. The rinsing water is used several times due to cascade rinsing.

- The clean water in this rinsing system flows in the opposite direction to the workpiece throughput and can thus be used several times.

- The dragged-out medium is thus completely captured and the surface quality of the workpieces is improved.

- The system consists of a slowly flowed through pre-rinse cascade and a final rinse stage with powerfully flowing circulated water.

- The workpieces with the highest concentration of active ingredients are immersed in the sink first ("dirt section"), then in rinse sections with constantly decreasing concentration. The cascade effect produced thereby is revealed by reducing required quantities of rinsing water with constant rinsing quality (rinsing criterion).

The transition from single-stage to two-stage rinsing technology causes the main effect of the saving; however, the electrolyte concentration achieved thereby in the first rinse section is usually not sufficient for direct return. Cascade swills are particularly efficient when just the same amount of water is used for removal of the electrolyte as the treatment bath loses in evaporation and drag-out losses (water balance reconciliation).