Temperature Monitoring

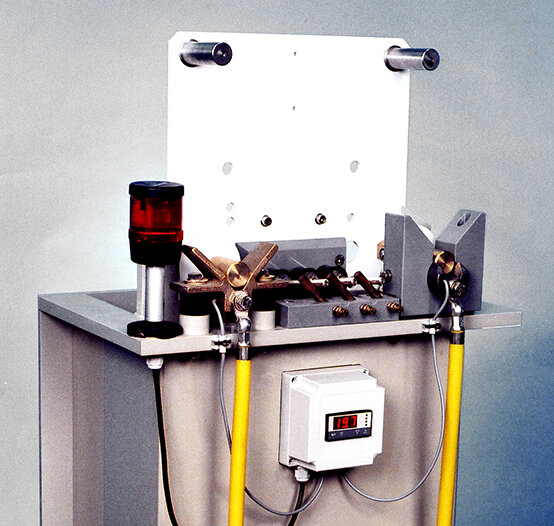

Temperature monitoring of electroplating system with GALVA-PROTECT

Due to the current transmission during galvanising, heating of the contact points occurs, caused by soiling and wear. These contact points can become fire triggers due to strong and uncontrolled heating. The safety system "GALVA-PROTECT" provides protection.

The temperature of the product current contacts is monitored using sensors.

Exceedance of any maximum temperature is automatically signalled to the plant control system.

The plant operator can thus initiate preventive countermeasures in good time and promptly detect the danger of a fire.

Downloads